- #Torson clock mini suspension unit cracked#

- #Torson clock mini suspension unit install#

- #Torson clock mini suspension unit full#

- #Torson clock mini suspension unit plus#

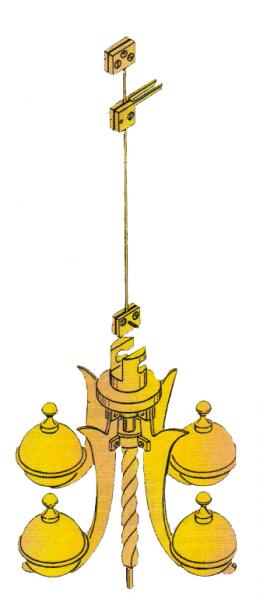

There is nothing fancy about the beat adjustment. Once installed on the movement it is time to test the beat. The locking guard is an earlier design and looks a somewhat flimsy but should work. Next is the back spring cover and the locking guard. The bottom block has two hanger pins that the pendulum rests on. There is a threaded thumbscrew on the top base that slips into the top block (arrow in photo above). The suspension spring assembly slipped into the top and bottom easily. Arrow indicates insertion point for top block The spring is longer than necessary and must be trimmed to fit. However, once I overcame that little issue the completed assembly looked exactly like the template. The bottom block was seized and it took an extra effort to release the two block screws. All went well until I got to the bottom block. The screws on the suspension assembly are very small and it pays to have good quality precision screwdrivers. Having a template at hand allows one to follow a pattern when screwing the fork and the upper and lower blocks to the suspension wire. In Section 10 of the guide there are templates for a number of clocks. If you do not have the time to assemble suspension units, Horolovar will gladly sell you completely assembled units but you pay much more.

The guide tells me that this 400 clock is a Kundo Standard 53 that uses a. The old spring was snapped off just above the bottom block and not re-usable. Unfortunately, I required a new suspension spring for this clock. For my first Kundo miniature (bought and serviced in 2015) I did not have the guide and after a lot of guessing and cursing I managed to get the suspension spring installed correctly but it was more luck than skill. I received my guide as a Christmas gift last year. The old spring was snapped off just above the bottom block and unfortunately it was not re-usable Horolovar 400 Day Clock Repair Guide Horolovar templates The guide takes the guesswork out completely. To perform servicing on a 400 day clock you must have the Horolovar 400 day Repair Guide as a reference. 400 day clocks are easy to disassemble/clean and re-assemble but getting it to work correctly can be frustrating.

#Torson clock mini suspension unit install#

The Horolovar suspension spring arrived today and now to install it in on the movement. Numerous dents, the pendulum locking guard is there for a reason! Not using it results in a snapped suspension spring and dents

#Torson clock mini suspension unit cracked#

The string still looks good the cover is cracked a little where it connects to the clock but isn’t falling off. I think it might need to be cleaned for it to do that. From my understanding these things are supposed to go for a whole day without being spun again.

#Torson clock mini suspension unit full#

The description is amusing: When I tested it, I spun the balls about a full turn and it continued to spin back and forth for several minutes.

#Torson clock mini suspension unit plus#

In fact, I saw one on EBay this morning (Oct 3, 2017) for 119US plus 39US shipping. I have never paid more that 30CDN for one but I see these clocks selling on EBay and other online for-sale sites at twice and three times what I typically pay. I have four anniversary clocks (otherwise known as torsion clocks). Attractive dial face, free of cracks and blemishes This a is Part II of a two part series on repairing a 400 day clock. I have never paid more that 30CDN for one but I see these clocks selling on EBay and other online for-sale sites at twice and three times what I typically pay

0 kommentar(er)

0 kommentar(er)